The scalable weLOAD model range offers solutions from infeeders for standard applications to high-end specialists and can therefore be flexibly adapted to your individual needs. In addition to an extremely compact…

Automation

With our automated transport, loading and infeeder solutions, you do not only simplify your processes, you also optimize the end result. In combination with other Weber components, sliced portions and products such as whole sandwiches can be transported, buffered and inserted with automation. The result is high output, minimal personnel costs and effort for maintenance as well as maximum hygiene and food safety.

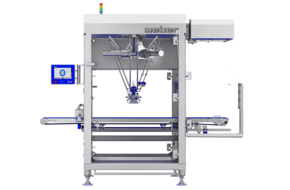

The Weber PickRobot stands for the uncompromising automation of slicing applications. Specifically adapted to your application area, it can be used flexibly for all insertion tasks and is available in five…

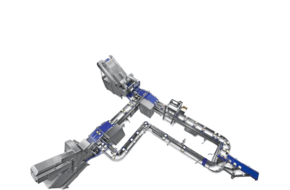

The Weber weSHUTTLE automated transport system offers a flexible alternative to transporting portions via belt systems. The weSHUTTLE conveys a wide variety of products and portions from various sources (e.g.…

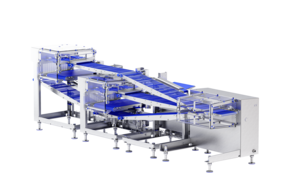

The Weber weSTACK 3500 enables the automatic and precise creation of stacks of layout bacon. This makes the weSTACK the ideal solution for food service applications. Portions are positioned perfectly thanks to the…

The Weber weSTACK creates stack of products such as carpaccio, bacon, salami, or cheese. This makes the weSTACK the ideal solution for food service applications. For maximum flexibility, both stacked and…

More power, more sustainability, better hygiene: that is the Weber weUNDERLEAVE. The underleaver automatically places paper or film under sausage, cheese or alternative protein slices and complete portions. The…

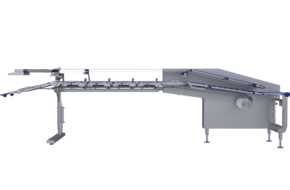

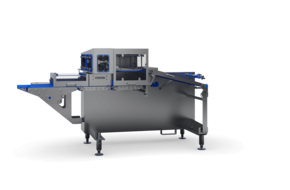

The compact Weber SmartLoader is a fully automatic side loading system for individual products or entire portions. It consists of a servo-motor-driven line-up conveyor and a grouping conveyor or loading conveyor.…