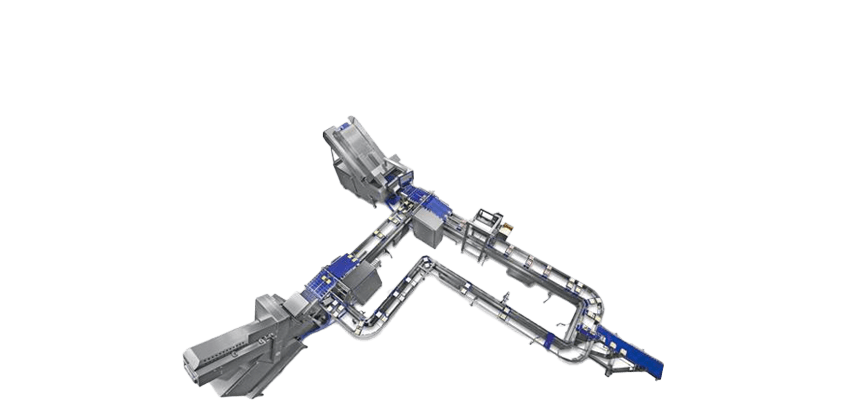

weSHUTTLE

- Individually adaptable to spatial conditions

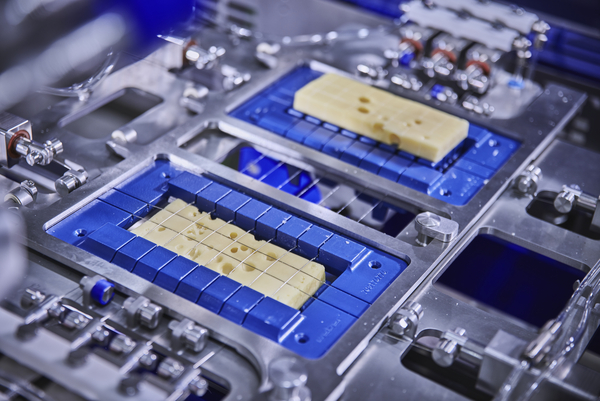

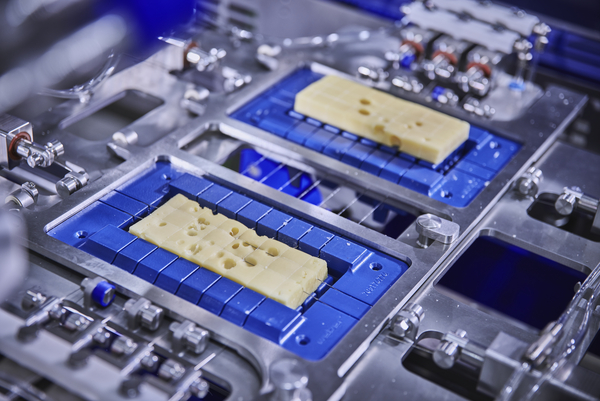

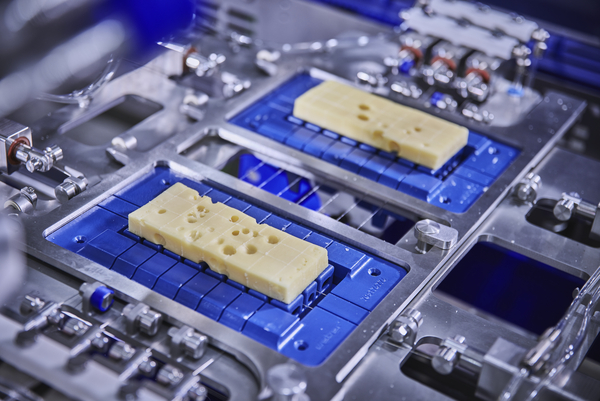

- Gentle transport of individual portions

- Expandable through components for flexible line concepts

- Ideal for manufacturing convenience products or generating variety packs

Versatile and incomparably flexible: the weSHUTTLE transport system.

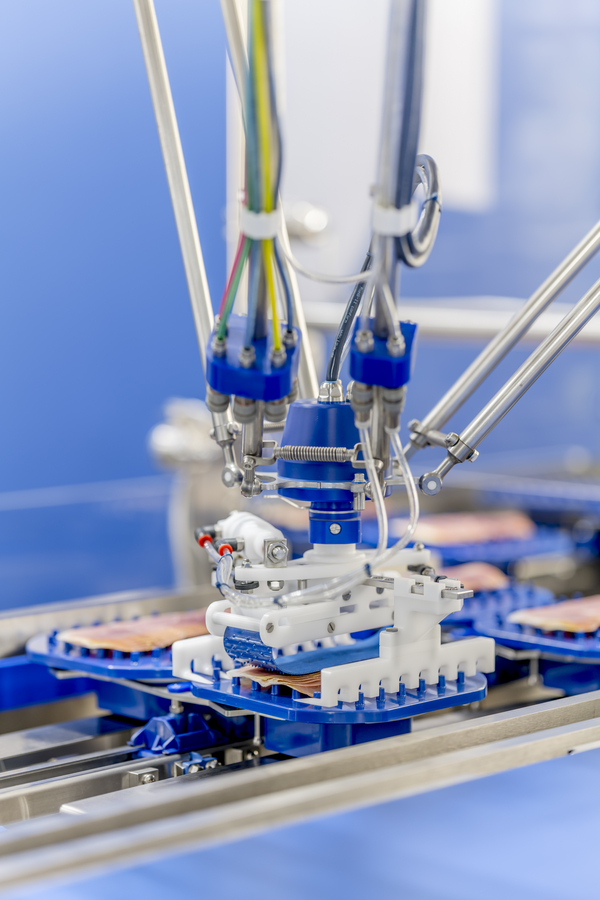

The Weber weSHUTTLE automated transport system offers a flexible alternative to transporting portions via belt systems. The weSHUTTLE conveys a wide variety of products and portions from various sources (e.g. slicers) precisely, gently and individually to one or more handover points on portion carriers that can be adapted to individual products. Where classic transport systems have limitations, the weSHUTTLE scores points with maximum flexibility: Among other things, it can be integrated in any desired room due to its flexible lane design. This not only saves valuable space but also hard cash and allows customized line configurations that can be tailored to individual spatial conditions and modularly expanded. In this way, the entire production area can be optimally utilized on a minimum footprint.

The Weber weSHUTTLE is ideally suited for the economic, flexible, and highly automated production of sliced-product variety packs or convenience products such as sandwiches, the automatic filling of all kinds of ready meals, as well as the automatic application of pizza toppings. A great challenge in the automated production of convenience products is especially being able to reproduce various speed requirements on a line. The speed has to be adapted depending on the production step – from a complete stop to a fast transport path to a reduced speed in the area of manual process steps. The Weber weSHUTTLE masters these challenges with flying colors. Thanks to the integrated buffer function, the weSHUTTLE combines a wide variety of portioning and dosing tasks, thereby guaranteeing a continuous, efficient, and optimum production process. These perfectly coordinated processes allow food manufacturers to increase throughput and save time and costs.

Technical Data — weSHUTTLE

Product Videos

Advantages

- Upstream and downstream machines are decoupled through the integrated buffer function, ensuring continuous production

- Flexibly expandable: from entry solutions to high-end lines for complex infrastructures (as a stand-alone solution or in combination with existing Weber slicers)

- High dynamics and the product transfer performance guarantee maximum throughput

- Use of diverters to connect different production cycles, for example, ready-meal or pizza applications

- Tool-free removal of portion carriers for fast intermediate cleaning

- Maximum hygiene for longer product shelf lives

- UVC disinfection to increase product safety (optional)