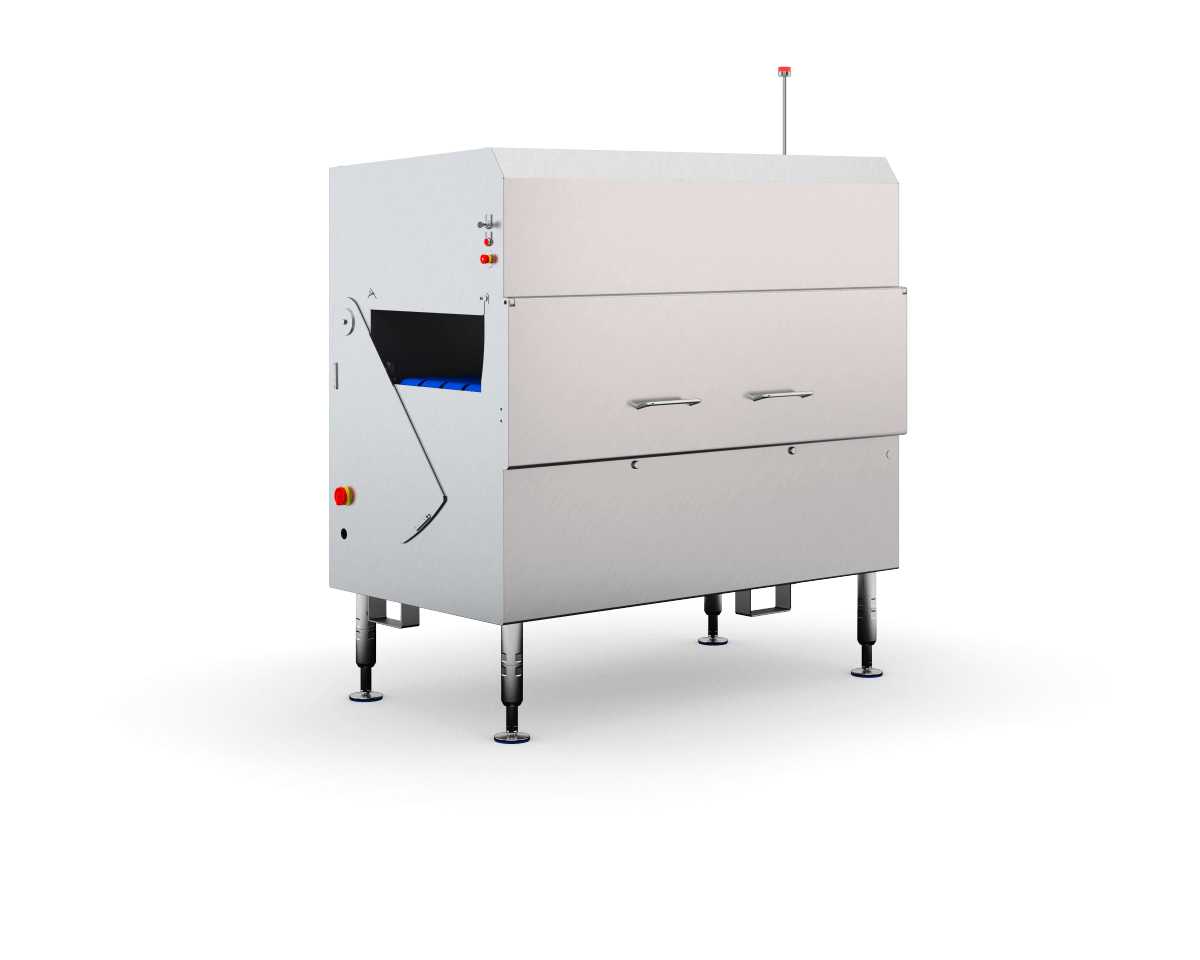

weSCAN 7000

Weber x-ray scanner: Exact measurement of product density and weight.

With the Weber weSCAN 7000 X-ray scanner, product density and weight can be precisely determined in order to achieve the best possible use of raw materials and thus achieve maximum yield. The use of an X-ray scanner is essential for economic production, especially for applications for cheese with eyes and products with large differences in density. Thanks to design optimization, even better hygiene conditions, and greater user-friendliness have been achieved with the weSCAN 7000 compared to the previous model. The operation is carried out via the operating terminal on the slicer, which ensures optimal accessibility to the slicer. The system features a two-stage safety guarding for its radiation source.

Product Videos

Advantages

- Particularly suitable for cheese with eyes applications

- Up to six products in one scan cycle

- Minimizes setup and downtimes through improved ergonomics and operating friendliness

- Easy to clean and hygienic thanks to reduced flaps and covers

- Foreign objects detection: stainless steel > Ø = 3 mm, glass/ceramic> Ø = 8 mm (product-dependent)

- Belt lengths available in 800 mm and 1,200 mm

Gallery

Contact