Revolutionizing Production of Snack and Convenience Products

Convenience products, charcuterie style for snacking, sandwiches and the rest – have continued to drive growth in deli and refrigerated retail, even post Covid surge. Capable of satisfying a wide variety of consumer demands – including the desire for variety, health forward and high quality options – the growth seen in convenience offerings is only expected to continue. That said, for you and your production systems, this growth potential can only be realized with carefully considered systems designed to overcome sometimes significant obstacles.

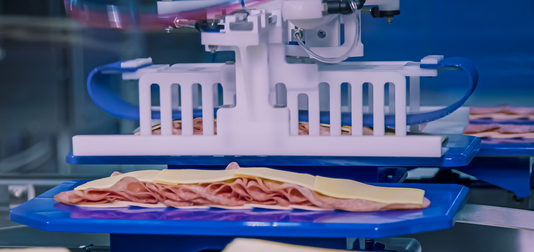

Overcome these obstacles with Weber and our solutions that creatively solve the convenience product challenge. From slicing and loading of charcuterie style products to handling systems that facilitate highly flexible production of snack tray, ready meal, and pizza solutions – our solutions will no doubt allow for more efficient convenience product production than ever.

Automation solutions for snacks & convenience products.

Saving personnel, reducing line length and floor space, avoiding manual processes and therefore increasing hygiene and food safety; with the help of Weber’s comprehensive automation, several challenges within convenience food production can be solved at once.

Let Weber provide it all for you! Get what you expect: scalable solutions with the highest level of automation, centralized control and seamless networking.

Diverse and safe packaging styles.

In addition to the appealing presentation at the point of sale, the protection and shelf life of your products are particularly important success factors. For you, this means more profitability and sustainability, for end consumers it means more food safety and taste. In doing so, the options for packaging forms are diverse. Depending on the product, thermoformed packaging, trays or shrink foil, for example, can be accepted styles of packaging.

Moreover, sustainability and resource-conservation are now relevant factors for consumers that have an influence on purchasing decisions and thus influence the development and design of snack and convenience products. Reduction of packaging material, recyclability and use of sustainable packaging materials - these and other aspects must be taken into account. Our experts will support and advise you on all topics concerning the design of your packaging as well as on the choice of the appropriate packaging material.