Slice, transport and package cheese efficiently.

Cheese in all its diversity presents a different, individual challenge at every processing step. With our line solutions, you can master the daily challenges of your cheese production.

Let yourself be inspired by our processing solutions for cheese: from weight-accurate slicing and perfect portioning to the desired presentation in the cheese packaging.

Integration. Flexibility. Efficiency. Throughout the entire line.

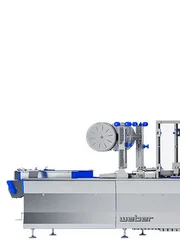

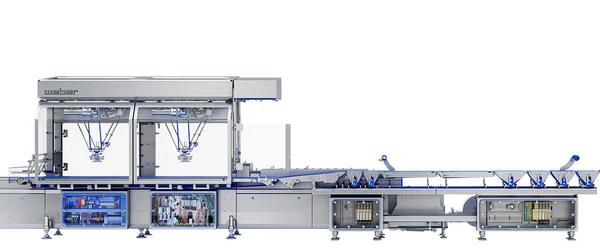

- Everything from one source: LED or X-Ray Scanner, Slicer, Infeeder, and End of Line Equipment

- Yield Maximizing Production - made possible with our "One Machine" philosophy.

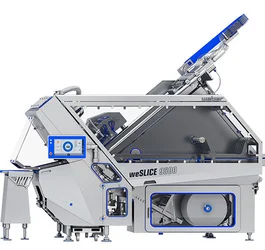

- Perfect interaction between cheese, machine, and blade with the Weber Durablade. Process and Knowledge honed against decades of experience.

- Vacuum Grippers reduce end piece size by up to 50%

- The market leader in output in every slicer class.

- More than 99% on weight production.

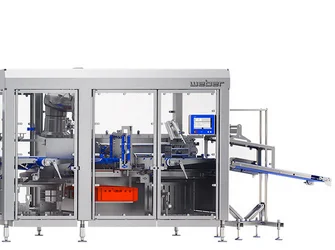

- Even during production, options exist to change applications or service machine components.

- Recipe change with the push of a button.

- Premium User friendliness with toolless change of belts, grippers, shear bars and product downholders.

Optimize your cheese production.

Vepo Cheese on the cooperation with Weber.

We have a long-standing, trusting relationship with many of our customers. Thanks to our experience, technical know-how, innovative developments and excellent service, we offer you real added value and are at your side as a strong partner. We are proud that cheese producers from all over the world trust in our solutions.

Dutch cheese processor Vepo Cheese has relied on production solutions from Weber for over 20 years. There are many reasons for this. Owner Mark Verkleij and technical operations manager Hugo van Put tell us why Weber is the number 1 in the cheese world for them and what else the companies have in common.

Cheese production with no limits, your way

Your customers' eyes make the purchase, every time. It doesn't matter which layout, presentation or type of portioning you want for your cheese application, we will put your product in the limelight effectively. With Weber technology there are no limits to your ideas, so whether you need shingled, stacked, overlapped or with interleaver sheets Weber has a solution for it.

We are looking forward to your message.

Cheese cubes, cheese pieces, and cheese slices on one line.

Our customer asked for the ability to process cubes, pieces, and slices of different types of cheese on one line and thus set a newstandard for flexibility in cheese processing. The changeover between the respective applications should take as little time as possible, of course, in order to maximize the line's operating time.

Flexible Weber line solution for versatile cheese applications.

Raclette cheese, Emmental, Appenzeller, Gruyère, each portioned out and presented differently – no problem at all for a Weber line! Our customer needed a flexible solution for processing versatile cheese applications.